Concrete Contractor adds a unique decorative element to walls, patios, and other surfaces. It’s a specialty technique that requires specialized tools and training to master.

Unlike overlay concrete, this sculptural process uses a unique mix designed for carving and texture stamping that mimics stone, brick, or wood. It dries as hard as or more complex than standard concrete.

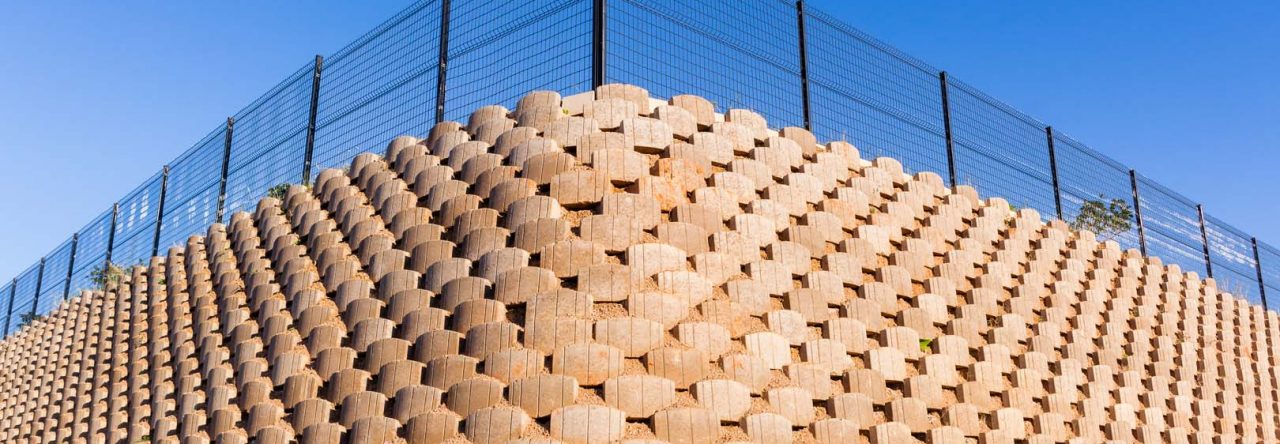

Concrete can be shaped and colored to resemble stone, rock or even chiseled wood for unique and one-of-a-kind decorative accents for walls, patios and other surfaces. Contractors who specialize in carved concrete can add a dramatic focal point to any home or business and make it stand out from the rest. When selecting a contractor to work on your project, look for one who is licensed and insured and has experience working with concrete. They should be able to provide references from previous clients, as well as photos of their work.

Carving into concrete can be done by hand or with a machine, and it allows contractors to produce a wide variety of patterns. A contractor who specializes in etched and carved concrete may also be able to offer custom markings and patterns that range from company logos to names and dates. This type of carved concrete can be used alone or in conjunction with other finishes, such as pattern stamping and textured overlays.

When a sculptural element is carved into concrete, the result is a relief carving. Unlike stone carving, which leaves the carved piece attached to the surface of the material, concrete carving in relief raises the design up off the background surface. This makes the design easy to clean and less susceptible to damage from ice or snow.

Whether the concrete is stamped, textured or carved, it can be finished with a high-quality sealer to protect it from dirt, rain and sun damage. A reseal every two to three years is typically recommended.

A good decorative concrete contractor will provide a detailed construction bid that includes the materials and labor needed to complete the work as described. This will help ensure that the final product will be consistent with the specifications and design and that the client is protected against any hidden fees or charges.

If the contractor is a member of a professional organization, such as the American Society of Concrete Contractors Decorative Concrete Council or the American Institute of Architects, they will be able to provide a certificate of insurance that proves that the company is insured and bonded. In addition, a member of a professional organization is likely to have up-to-date training on new concrete technologies and procedures.

Concrete engraving is an artisan trade that utilizes a precision cutting machine to cut patterns into the surface of existing concrete. The result is a permanent treatment that will not wear away like toppings or overlays. It also requires less maintenance than stained concrete and will look good for the life of the surface.

Concrete engravers are trained to use specialized tools to give existing concrete the look of hardwood, marble, tile, cobblestone or epoxy flooring. They can even carve company logos and custom designs. They can also add color to the concrete with chemical staining. The color is injected into the concrete and reacts with the minerals in the stone. The resulting color tones are uneven and mottled, creating a dramatic effect.

Decorative treatments are popular for new concrete, but what about the millions of square feet of naked concrete already in existence? Naked concrete is a big market for decorative treatment specialists. The concrete can be treated with pattern stamping, exposed aggregate or textured finishes. However, these techniques require significant product, employee, and equipment expenses to produce a desirable result.

A concrete engraver is the key to this type of niche business. The most common concrete engraver is the Mongoose 411. It has a powerful motor and an adjustable cutting depth that can be adjusted with the turn of a knob. It can be used on any size or shape of concrete surface. The patented tool is easy to learn and offers great profit potential for its owners.

While the average salary at a company may vary depending on its location, industry and department, the salary for a Concrete Engraver is around $68,990. This is higher than the average for the industry.

There is little to no concrete dust created during a concrete engraving job, so there is no respiratory hazard. However, concrete debris can create an eye hazard if it gets in the eyes. For this reason, the artisan should wear protective goggles and gloves during the process. In addition, it is important to keep the concrete wet while cutting it to prevent abrasions and other damage.

Concrete can be treated with a number of decorative treatments, such as pattern stamping, exposed aggregate and textured overlays. But what about an existing plain gray concrete driveway, sidewalk or patio that’s in need of some dramatic and lasting decorative flair? Engraving or etching, with the help of specialized tools and equipment, is one answer. These processes use special tools to cut patterns and designs into cured concrete, leaving one-of-a-kind markings or designs that won’t wear away like toppings or overlays.

Decorative contractors who specialize in etching and engraving concrete can make a huge impact on a client’s home or business by giving the structure an appearance that resembles stone, pavers or even wood planks. First, they level and pour a new slab of concrete, then use rubber stamps to shape it into the form of the desired material. Then they add color with concrete stains that match the stone or wood they’re trying to mimic. When the stain dries, they can use a specialized tool called a Shark to etch and carve the concrete in relief, creating a finish that looks authentic and sets the property apart from others.

Another way a contractor can etch and carve concrete is to use a hand-held percussive engraving tool guided by templates, which are available in thousands of patterns and designs, including letters, logos, borders and custom graphics. The system also can be used freehand, which opens up the possibilities for more intricate or one-of-a-kind work.

The system was developed by Darrel Adamson, whose background includes remodeling contractor work and a stint as a decorative concrete contractor. arm contractors with all the tools they need to master etching and carving concrete and achieve professional results.

Adamson recently demonstrated his etching and carving skills at a seminar held in . He created a line drawing of an eagle with an eight foot four inch wingspan on a slab of concrete, then scanned the image into a computer program and enlarged it. Carpenter’s pencils were then used to trace the outline, and the concrete was stained with DecoSup concrete dyes that matched the eagle’s feathers. The eagle was then engraved with the Shark, and epoxy filling was done to complete the project.

Carving and coloring concrete on vertical surfaces is a growing niche. For contractors who have the right skills and tools, this new market offers good money and creative freedom. However, before you start a carved concrete project, make sure you have the right materials and a good plan for the job. Also, make sure you wear gloves and a dust mask while working with concrete, as it contains silica that can irritate the skin and lungs over long periods of time.

Carved concrete is an artistic method of replicating stone and wood with concrete. It is often used for fireplaces, patios, walls and other outdoor features that need to look like natural rock or stone. Expertly applied, this decorative concrete technique can create a unique one-of-a-kind feature that sets the property apart from others.

To get started with a carved concrete project, you need a good concrete mix and a variety of carving tools. It is important to choose a concrete mix that includes high levels of finely graded sand and polymers to ensure good workability and durability. Also, you should use a thin-set tile mortar that has added polymers to promote adhesion. It is a good idea to add a little clay to the concrete mixture, as it will suck up moisture and help the mix stay stiffer and more workable.

Once the concrete has been poured, you can texture it using special rollers, skins or stamps that imitate a specific material. This method can be used to create a range of finishes, from smooth to textured and patterned. Some installers also hand carve into the concrete to add detail and improve realism.

When a concrete contractor sculpts into a slab of cured concrete, the resulting surface is called a relief. The carved pattern is often raised above the background plane of the concrete, but it can also be lowered into the surface. The carved concrete is then polished to reveal the relief pattern beneath.

Creating a custom concrete countertop can be a great way to enhance the look of a home or business. It can also serve as an alternative to more expensive building materials. But before you hire a contractor to do the job, it is important to check their body of work and reputation. You should also consider if they have the proper training and licenses to operate in your area.